उत्पाद विवरण:

एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट को विशेष रूप से खतरनाक वातावरण में विश्वसनीय और सुरक्षित विद्युत कंड्यूट समाधान प्रदान करने के लिए इंजीनियर किया गया है, जिसकी विशेषता गैस और धूल की उपस्थिति है। विस्फोटक वातावरण अनुप्रयोगों की सख्त आवश्यकताओं को पूरा करने के लिए डिज़ाइन किया गया, यह कंड्यूट परिचालन सुरक्षा सुनिश्चित करने और उद्योग मानकों के अनुपालन में एक आवश्यक घटक है। इसका उपयोग आमतौर पर उन वातावरणों में किया जाता है जैसे रासायनिक संयंत्र, तेल रिफाइनरी, खनन संचालन, और अन्य औद्योगिक सेटिंग्स जहां चिंगारी या विद्युत दोषों के कारण प्रज्वलन का जोखिम कम किया जाना चाहिए।

इस कंड्यूट की सबसे खास विशेषताओं में से एक है इसे नॉन-स्पार्किंग फ्लेक्स कंड्यूट के रूप में वर्गीकृत करना। इसका मतलब है कि इसे इस तरह से बनाया गया है कि स्थापना या संचालन के दौरान चिंगारी उत्पन्न होने से रोका जा सके, जिससे विस्फोटक वातावरण में प्रज्वलन का जोखिम काफी कम हो जाता है। यह आंतरिक सुरक्षा सुविधा इसे उन क्षेत्रों में उपयोग के लिए अत्यधिक उपयुक्त बनाती है जिन्हें ज्वलनशील गैसों या दहनशील धूल कणों की उपस्थिति के कारण खतरनाक के रूप में वर्गीकृत किया गया है।

कंड्यूट को इंट्रिंसिक सेफ्टी शीथिंग कंड्यूट के रूप में भी जाना जाता है, जो विद्युत तारों के लिए सुरक्षा की एक अतिरिक्त परत प्रदान करने में इसकी भूमिका पर जोर देता है। शीथिंग को आंतरिक कंडक्टरों को बाहरी यांत्रिक क्षति और संक्षारक पदार्थों से अलग करने और उनकी रक्षा करने के लिए डिज़ाइन किया गया है, साथ ही किसी भी चिंगारी या विद्युत दोष को कंड्यूट से बाहर निकलने और आसपास के वातावरण को प्रज्वलित करने से रोकने के लिए भी डिज़ाइन किया गया है। यह आंतरिक सुरक्षा डिज़ाइन सुनिश्चित करता है कि कंड्यूट विस्फोटक वातावरण में आवश्यक उच्चतम सुरक्षा मानकों को पूरा करता है।

अपनी सुरक्षा सुविधाओं के अलावा, एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट में उत्कृष्ट सुरक्षा रेटिंग है, विशेष रूप से IP66 और WF2। IP66 रेटिंग गारंटी देती है कि कंड्यूट धूल-रोधी है और शक्तिशाली पानी के जेट से सुरक्षित है, जो इसे कठोर पर्यावरणीय परिस्थितियों में उपयोग के लिए उपयुक्त बनाता है जहां धूल का प्रवेश और नमी अन्यथा विद्युत अखंडता से समझौता कर सकती है। WF2 रेटिंग आगे इसकी मौसम प्रतिरोधी गुणों के साथ बाहरी उपयोग के लिए उपयुक्तता की पुष्टि करती है, जो चुनौतीपूर्ण मौसम की स्थिति में भी लंबे समय तक प्रदर्शन सुनिश्चित करती है।

लचीलापन इस कंड्यूट का एक और महत्वपूर्ण गुण है। यह अत्यधिक लचीला है, जो जटिल रूटिंग परिदृश्यों में आसान स्थापना की अनुमति देता है जहां कठोर कंड्यूट सिस्टम का उपयोग अव्यावहारिक या असंभव होगा। लचीलापन स्थापना के समय और श्रम लागत को भी कम करता है, जिससे यह खतरनाक स्थानों में व्यापक वायरिंग परियोजनाओं के लिए एक किफायती विकल्प बन जाता है। सुरक्षात्मक आवरण या विद्युत निरंतरता से समझौता किए बिना झुकने और घुमावदार होने की इसकी क्षमता इसे तंग जगहों या बाधाओं के आसपास विशेष रूप से मूल्यवान बनाती है।

एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट विभिन्न आकारों में उपलब्ध है, जिसमें जी, एम और एनपीटी थ्रेडिंग विकल्प शामिल हैं, जो विद्युत फिटिंग और कनेक्टर्स की एक विस्तृत श्रृंखला के साथ संगतता प्रदान करते हैं। आकार में यह बहुमुखी प्रतिभा सुनिश्चित करती है कि इसे व्यापक संशोधनों की आवश्यकता के बिना मौजूदा विद्युत प्रणालियों में निर्बाध रूप से एकीकृत किया जा सकता है, जिससे सुविधा और लागत-प्रभावशीलता दोनों में वृद्धि होती है।

रासायनिक प्रतिरोध एक और महत्वपूर्ण विशेषता है, क्योंकि यह कंड्यूट औद्योगिक वातावरण में आमतौर पर पाए जाने वाले रसायनों की एक विस्तृत श्रृंखला के लिए अच्छा प्रतिरोध प्रदर्शित करता है। यह रासायनिक प्रतिरोध सुनिश्चित करता है कि कंड्यूट संक्षारक एजेंटों, तेलों, सॉल्वैंट्स और अन्य खतरनाक पदार्थों के संपर्क में आने पर भी अपनी संरचनात्मक अखंडता और सुरक्षात्मक क्षमताओं को बनाए रखता है। यह स्थायित्व कंड्यूट के जीवनकाल को बढ़ाता है और रखरखाव आवश्यकताओं को कम करता है, जिससे सुरक्षित और अधिक विश्वसनीय संचालन में योगदान होता है।

कुल मिलाकर, एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट विस्फोटक वातावरण से जुड़े जोखिमों के खिलाफ मजबूत सुरक्षा की आवश्यकता वाले अनुप्रयोगों के लिए एक अपरिहार्य समाधान है। नॉन-स्पार्किंग फ्लेक्स कंड्यूट डिज़ाइन, इंट्रिंसिक सेफ्टी शीथिंग कंड्यूट निर्माण, उच्च IP66 और WF2 सुरक्षा रेटिंग, उत्कृष्ट रासायनिक प्रतिरोध और बेहतर लचीलेपन का संयोजन इसे गैस और धूल वातावरण में सुरक्षा, स्थायित्व और प्रदर्शन सुनिश्चित करने के लिए आदर्श विकल्प बनाता है। चाहे नई स्थापनाओं के लिए या मौजूदा प्रणालियों को अपग्रेड करने के लिए, यह कंड्यूट महत्वपूर्ण सुरक्षा मानकों के साथ मन की शांति और अनुपालन प्रदान करता है।

विशेषताएँ:

-

उत्पाद का नाम: एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट

-

सामग्री: बेहतर स्थायित्व और लचीलेपन के लिए रबर/स्टेनलेस स्टील

-

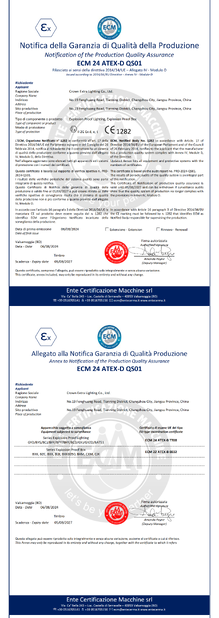

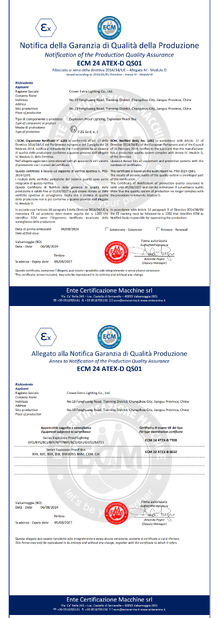

Ex मार्क: Ex Db IIC T6 Gb, Ex Tb IIIC T80°C Db प्रमाणित

-

अनुप्रयोग क्षेत्र: डिवीजन 1, 2, 21 और 22 खतरनाक स्थानों के लिए उपयुक्त

-

खतरनाक स्थानों के लिए उपयुक्त: हाँ, विशेष रूप से विस्फोटक वातावरण के लिए डिज़ाइन किया गया

-

आइटम प्रकार: पूर्व प्रूफ फ्लेक्सिबल पाइप कंड्यूट

-

दहनशील गैस सुरक्षित कंड्यूट ट्यूब सुरक्षा प्रदान करता है

-

विस्फोटक वातावरण में सुरक्षा सुनिश्चित करते हुए एक दहन प्रूफ कंड्यूट पाइप के रूप में कार्य करता है

-

विश्वसनीय प्रदर्शन के लिए एक विस्फोटक वातावरण सुरक्षित नली के रूप में कार्य करता है

तकनीकी पैरामीटर:

|

लचीलापन

|

अत्यधिक लचीला

|

|

अनुप्रयोग क्षेत्र

|

डिवीजन 1 2 और 21 22

|

|

Ex मार्क

|

Ex Db IIC T6 Gb, Ex Tb IIIC T80°C Db

|

|

आकार

|

G / M / NPT

|

|

अनुप्रयोग

|

गैस और धूल का वातावरण

|

|

सामग्री

|

रबर / स्टेनलेस स्टील

|

|

सुरक्षा

|

IP66 WF2

|

|

प्रमाणन

|

ATEX

|

|

अनुकूलित सेवाएँ

|

उपलब्ध

|

|

खतरनाक स्थानों के लिए उपयुक्त

|

हाँ

|

अनुप्रयोग:

क्राउन एक्स्ट्रा एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट, मॉडल नंबर बीएनजी, चीन से उत्पन्न एक प्रीमियम उत्पाद है, जिसे विशेष रूप से उन वातावरणों के लिए डिज़ाइन किया गया है जिनमें उच्चतम स्तर की सुरक्षा और विश्वसनीयता की आवश्यकता होती है। ATEX द्वारा प्रमाणित, यह कंड्यूट खतरनाक स्थानों में उपयोग के लिए आदर्श है जहां विस्फोटक वातावरण मौजूद हो सकता है। इसका इंट्रिंसिक सेफ्टी शीथिंग कंड्यूट यह सुनिश्चित करता है कि विद्युत तारों को चिंगारी और प्रज्वलन स्रोतों से पूरी तरह से सुरक्षित रखा जाए, जिससे यह ज्वलनशील गैसों, वाष्पों या धूल से निपटने वाले उद्योगों के लिए एक आवश्यक घटक बन जाता है।

यह एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट अत्यधिक लचीला है, जो सुरक्षा से समझौता किए बिना सीमित या जटिल स्थानों में आसान स्थापना की अनुमति देता है। इसका लौ रिटार्डेंट फ्लेक्स कंड्यूट निर्माण आग के लिए उत्कृष्ट प्रतिरोध प्रदान करता है, यह सुनिश्चित करता है कि किसी घटना की स्थिति में, कंड्यूट आग को रोकने और आग के प्रसार को रोकने में मदद करता है। कंड्यूट का रासायनिक प्रतिरोध भी उल्लेखनीय है, जो इसे तेलों, सॉल्वैंट्स और अन्य कठोर रसायनों के संपर्क में आने वाले वातावरण में उपयोग के लिए उपयुक्त बनाता है, जिससे विद्युत प्रणालियों का जीवनकाल और विश्वसनीयता बढ़ जाती है।

IP66 WF2 रेटिंग के साथ, क्राउन एक्स्ट्रा बीएनजी कंड्यूट धूल और पानी के प्रवेश के खिलाफ बेहतर सुरक्षा प्रदान करता है, जो बाहरी या औद्योगिक सेटिंग्स में महत्वपूर्ण है जहां कठोर मौसम या नमी का जोखिम आम है। जी, एम और एनपीटी आकारों में उपलब्ध, इस कंड्यूट को विशिष्ट स्थापना आवश्यकताओं को पूरा करने के लिए अनुकूलित किया जा सकता है, जो अनुप्रयोग में लचीलापन प्रदान करता है। उत्पाद को 1SET/CTN के सेट में पैक किया जाता है, जिसमें केवल एक सेट की न्यूनतम ऑर्डर मात्रा होती है, जो छोटे पैमाने की परियोजनाओं और बड़े औद्योगिक मांगों दोनों को पूरा करती है।

इस विस्फोटक वातावरण सुरक्षित नली के लिए विशिष्ट अनुप्रयोग अवसरों में तेल और गैस सुविधाएं, रासायनिक संयंत्र, खनन संचालन और कोई भी औद्योगिक वातावरण शामिल हैं जहां विस्फोट-प्रूफ विद्युत सुरक्षा अनिवार्य है। यह विनिर्माण संयंत्रों, रिफाइनरियों और अपतटीय प्लेटफार्मों में उपयोग के लिए भी अत्यधिक उपयुक्त है जहां इंट्रिंसिक सेफ्टी शीथिंग कंड्यूट परिचालन सुरक्षा के लिए महत्वपूर्ण है। उत्पाद का डिलीवरी समय 5 से 10 दिनों तक होता है, जो प्रति माह 5000 सेट की एक मजबूत आपूर्ति क्षमता द्वारा समर्थित है, जो तत्काल परियोजनाओं के लिए समय पर उपलब्धता सुनिश्चित करता है।

ग्राहक क्राउन एक्स्ट्रा की अनुकूलित सेवाओं से लाभान्वित होते हैं, जो अद्वितीय परियोजना विशिष्टताओं को पूरा करने के लिए अनुरूप समाधान सक्षम करते हैं। भुगतान की शर्तें लचीली हैं, जिसमें 50% अग्रिम और डिलीवरी पर 50% की आवश्यकता होती है, जिससे खरीद सीधी हो जाती है। $1 से $200 तक की मूल्य सीमा के साथ, यह एक्सप्लोजन प्रूफ फ्लेक्सिबल कंड्यूट मांग वाले वातावरण में सुरक्षा और स्थायित्व के लिए उत्कृष्ट मूल्य प्रदान करता है। चाहे लौ रिटार्डेंट फ्लेक्स कंड्यूट या विस्फोटक वातावरण सुरक्षित नली के रूप में उपयोग किया जाए, क्राउन एक्स्ट्रा बीएनजी मॉडल खतरनाक स्थानों में आंतरिक सुरक्षा और सुरक्षा के लिए एक विश्वसनीय विकल्प के रूप में खड़ा है।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!